Every brand that values the customer's unboxing experience ships its products in elegant, durable boxes. Why? Because such packaging immediately win their customers' hearts. But how to get the perfect box when there are so many packaging choices out there? Let's talk about two of the top-tier packaging boxes every business uses nowadays - the RSC box and the Die Cut Cardboard box.

Die Cut Cardboard Boxes Vs. RSC Boxes - The Basics

If you are new to packaging and don't know what an RSC box is or how Die Cut packaging is different, we have got your back. Let's start with the basics and look into what each box is before getting into what sets them apart.

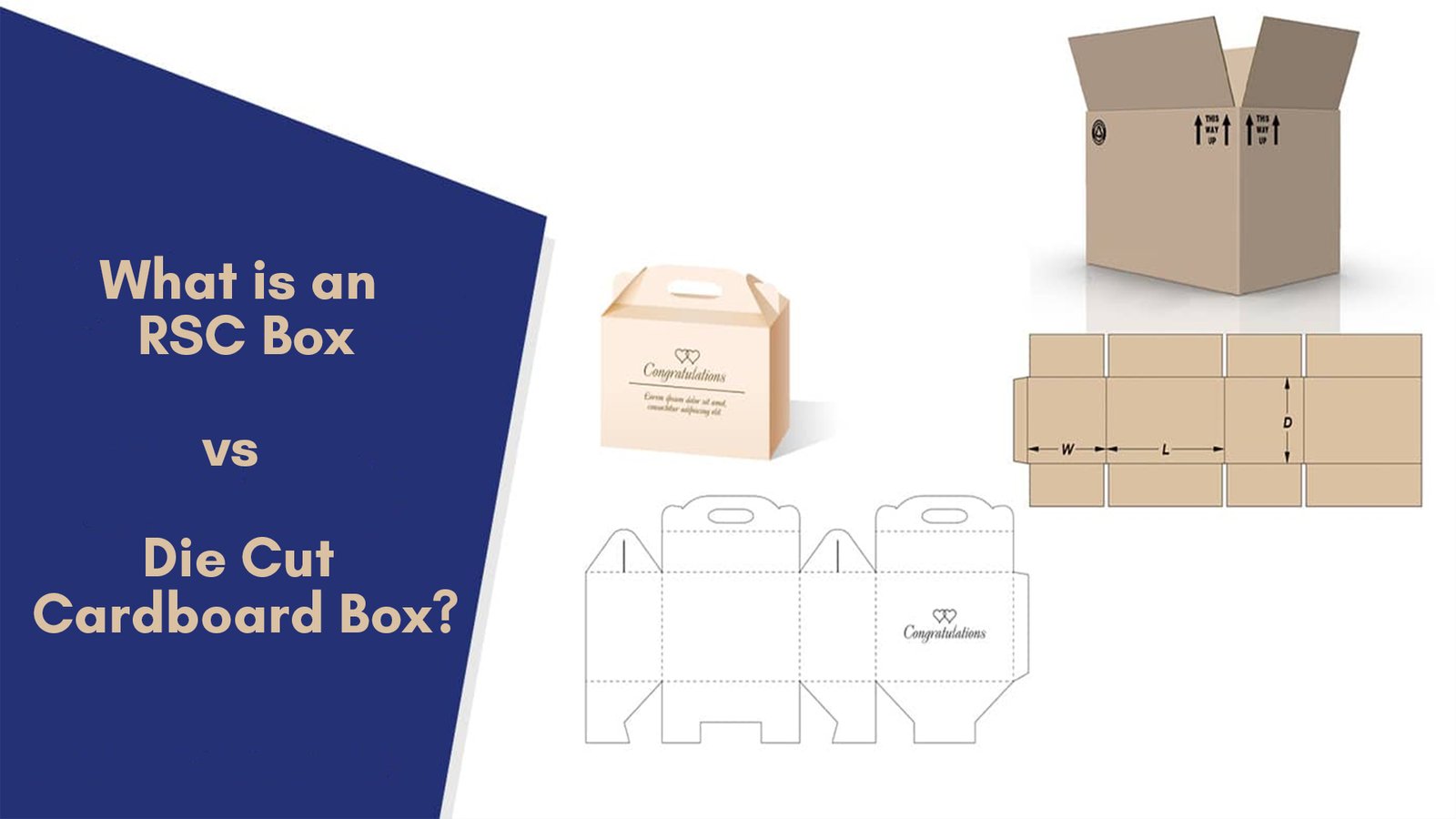

- Die Cut Cardboard Boxes

These boxes get their name from their production method. They are made by the die-cutting process, where a cardboard die cutter cuts corrugated cardboard into boxes. This process helps manufacture boxes in a wide array of shapes and styles. Thus making them a popular choice of packaging for countless brands.

- RSC Boxes

RSC is an acronym for Regular Slotted Container, which is created from a single sheet of cardboard that comes in a predefined or standard size. These boxes are simple and typically contain four flaps that need to be tapped together for secure and safe delivery of items.

What Makes These Boxes Different From Each Other?

Simply put, both are corrugated box styles with different manufacturing processes and different strengths. Here are a few key details to help you understand how exactly each box is different and which could be better suited for a brand.

- Difference In Design

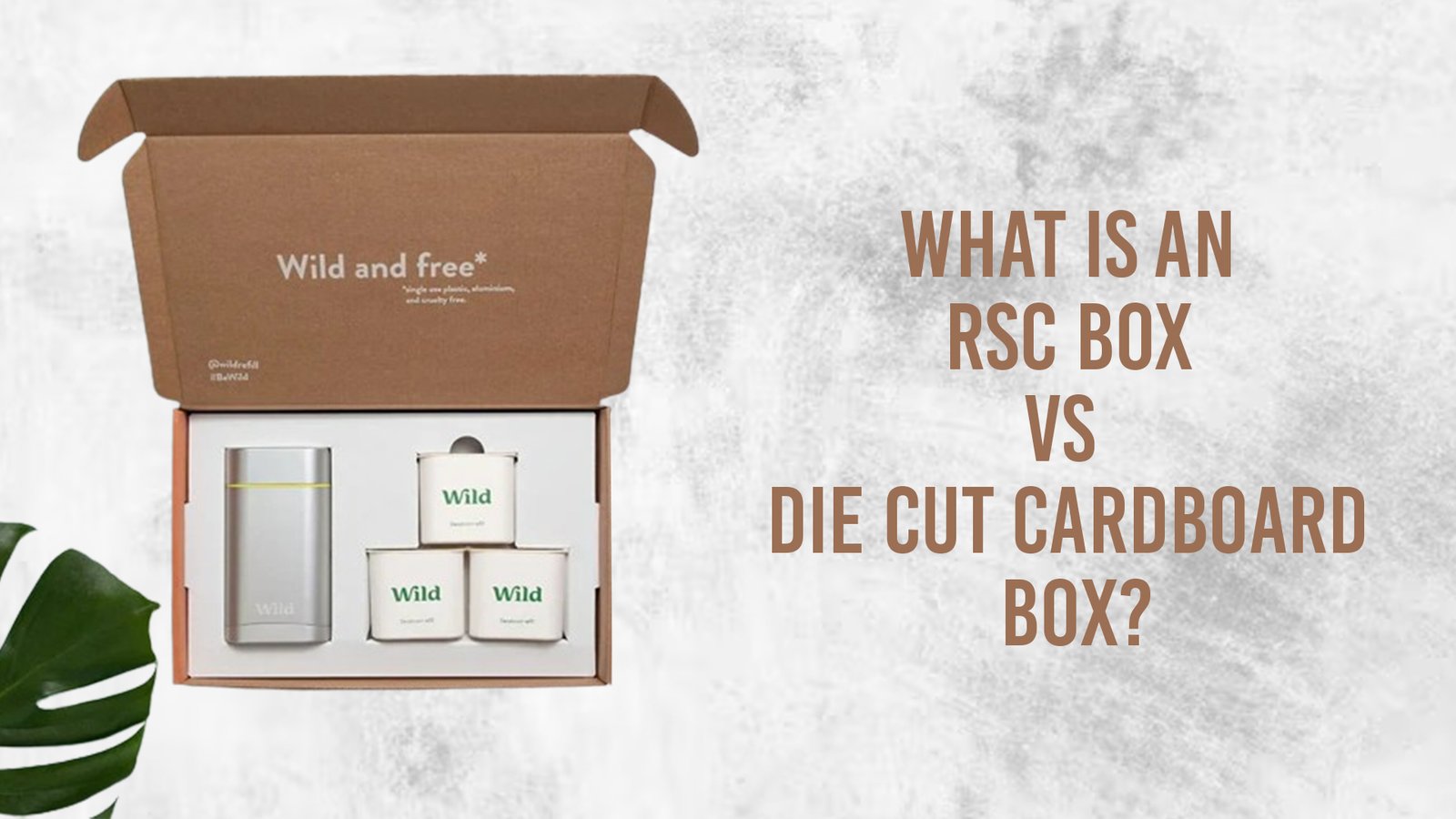

The most popular choice for brands (that sell cosmetics, jewelry, fragrances, watches, apparel, and so on) is the die cut box because it can be easily customized to suit the shape and size of their products. They are cost-effective yet made with high-quality materials. This allows brands to give customers a personalized shopping experience without jumping through hoops.

On the other hand, an RSC style box typically comes in a standard rectangular shape and is fixed in size. The standard sizes often used to ship small items is 4" x4" x4", whereas the best box size for shipping medium items is 9" x9" x9". That is why brands need to choose the exact shape and size of the RSC box beforehand to match the dimensions of their products. These boxes often require additional packaging to fill the empty space and keep the product safe.

- Variation In Materials

Die cut packages can be made using cardboard, kraft, corrugated, or rigid sheet materials to suit your product. The usual thickness of a Die Cut Box often ranges between 9pt to 24pt.

On the contrary, brands often make RSC packages using sustainable or recyclable corrugated sheets containing three layers, i.e., inner, outer, and flute layers. The thickness of these boxes also varies and can be chosen by the flute type, such as A, B, C, E, or F.

Customizable VS Standardized Assembly

As discussed already, Die Cut cardboard boxes are customizable and come in various styles and shapes, some of which are listed as follows:

- Straight tuck-top boxes

- Reverse tuck-top boxes

- Sleeve boxes

- Two-piece boxes

Most of these styles have special locking flaps that don't require any additional adhesives and maintain their structural integrity.

However, the RSC package requires additional adhesives such as glue or tape to hold its shape and keep contents secure inside. Its flaps are flat and simple, which means they don't have any special locking mechanisms, unlike the die cut packaging boxes.

Affordability VS Cost-efficiency

Since a die-cut cardboard box can be easily customized to the desired shape, style, and size, it is unlikely that it would cost more than a simple RSC packaging box. While RSC boxes are cheaper and have better stackability, the die-cut ones are more popular, especially when it comes to giving customers a bespoke experience and improving brand recognition.

Minimum Order Quantities

Die cut packages also have the upper hand over RSC packaging in this arena. Most packaging solutions offer minimum order quantities for the orders of custom die cut cardboard box. However, the RSC box does not enjoy this privilege. Most companies require you to purchase them in larger quantities.

Now that we have reviewed the basics and pros and cons of each box, let's see why brands must get their boxes from professional packaging manufacturers, such as Custom Boxes Only.

Why Get Your Boxes From Custom Boxes Only?

CBO is a professional packaging manufacturer. We always use high-quality materials to make custom boxes. You can get both RSC style boxes and die cut boxes in the size and thickness of your choice from us. However, we are experts in manufacturing shelf-ready die cut boxes. Our services include everything from beginning to end. For instance;

- Designing the boxes

- Printing brand logo and name on the box with desired typography

- Create packages with the desired color on the CMYK palette

- Include add-ons like branded wrapping papers, ribbons, cards, stickers, etc.

- Laminations - matte, gloss, UV-treated, and so much more.

So, talk to our team today and get your high-end packages, be it an RSC box or a Die Cut Cardboard Box. We are here for you.