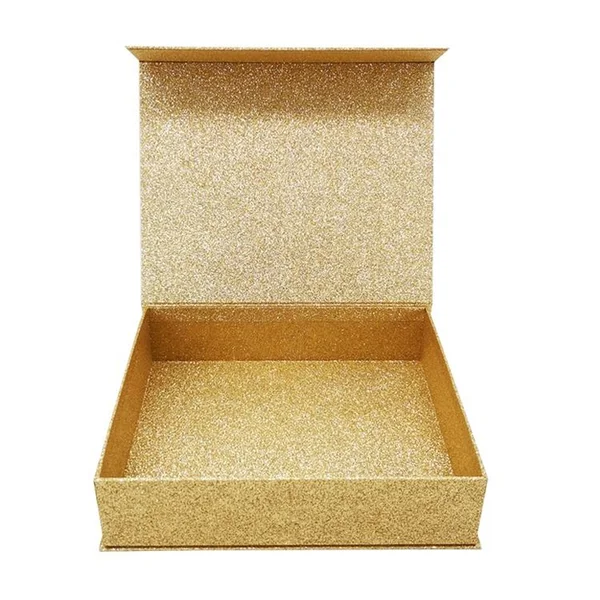

Custom glitter boxes contain information printed in an eye-catching manner. For instance, it can contain the company name and logo. These boxes can also include relevant graphics and photos. It makes it easier to attract target customers and raise revenue through increased sales. This box may also include puzzles, board games, or printed drawings. Most users prefer a variety of environmentally safe materials to manufacture them. These materials also come in a variety of thicknesses, ranging from 10pt to 28pt. There are no adverse environmental repercussions of these materials.

These boxes come with bespoke printing according to the product present inside them. Their common shapes are cubic, round, square, and hexagonal. They are also available in a range of sizes and colors. Their numerous sections, placeholders, and customized inserts are essential to improve the presentation of packaged items. Die-cut windows are essential for increasing product exposure in custom boxes. Customers can see the items within the boxes due to these windows. Their carriage may be easier from one place to another due to their handles. Magnetic closures can aid in preventing any threats to the products inside. This packaging also comes with the printed name and logo of the company.

The contents packaged inside custom glitter boxes must be safe. We use the finest and sturdy materials in their manufacturing.

Custom glitter boxes to improve security

We make sure the boxes come with the features that maintain the product clean and safe throughout the supply chain. We insulate them to maintain a consistent temperature if your products need it. It also maintains the temperature of products during transportation. It also prevents germs and bacteria from forming and growing. You can also get the box with airtight closures such as magnetic or Velcro lids. The packaging contains tamper-evident seals that indicate whether the box has been opened. It improves the product's dependability and safety. We exclusively utilize sturdy materials to manufacture these packages. These materials don't contaminate the products during storage or transit. Our packaging protects products from damage during shipping. It is because our packaging can absorb shock. Thus, you can get packaging with additional safety elements from us.

Exceptional printing

Custom boxes with premium printing are essential for marketing and branding.

Customboxesonly.com prints high-resolution packaging with your brand's logo displayed on it. In this way, distinctive and vibrant logos improve brand identification. Moreover, the packaging ought to have excellent images of products. It helps customers know about the quality of the products. Our team also makes sure that printing maintains color integrity. The packaging appears great when the colors are authentic and uniform. Our staff can also print put product details on a box. We list details like the type of product, weight, nutritional value, certifications, and quality requirements. We also ensure the usage of readable fonts to make textual content easier to understand. You can also get glitter boxes wholesale with printed barcodes and QR codes. They are crucial for easy traceability and information access on the sources, processing, and sustainability of products.

The adherence of glitter packaging to the rules

You need to follow the standards while constructing boxes to guarantee the safety and quality of products. It is also important to maintain supply chain transparency. Materials used to make product boxes must be suitable for food contact if you need to package food items inside glitter packaging. These food items shouldn't come into contact with any hazardous materials or contaminants. We also confirm that the packaging for the food products satisfies FDA or regional food safety regulations. The EU's Food Contact Materials Regulation (EC) No 1935/2004, which regulates food-contact materials, is another regulation that our team makes sure is followed. We also stay away from Bisphenol A (BPA). This is prohibited in a number of nations due to health issues.

Printing and finishing options

Custom glitter boxes require precise finishing and printing to look good and distinctive. Traditional offset printing is ideal for detailed and high-resolution artwork. It also gives glitter boxes brilliant colors. Digital printing is also great for shorter runs. It's economical for lesser quantities of boxes. Our team may also apply glitter coating directly to the box to sparkle. The coating can be full or partial, depending on your design. We can also use specialty glitter inks to print certain design elements. This allows accurate glitter application.

A glossy coating also makes the colors pop and smooths the box. Similarly, matte lamination can give a classier and muted look. It gives a non-reflective finish to your product boxes. Embossing helps to create three-dimensional effects by raising design sections. This gives bespoke boxes depth and substance. Our team can also apply shiny or holographic foil to a box for a premium look. Foil stamping enhances sparkle and aesthetics. We can also print your logo, tagline, or other branding features in the design. This makes your glitter boxes seem good and enhances your brand.

Dimensions Dimensions

|

All custom sizes & shapes |

Min.quantity Min.quantity

|

50 Boxes ( Hardproof Sample Option Available ) |

Default process Default process

|

Die cutting, gluing, scoring, perforation |

Printing Printing

|

Cmyk, pms, no printing |

Options Options

|

Custom window cut out, gold/silver foiling, embossing, raised ink, pvc sheet.

|

Turn around time Turn around time

|

10-12 business days , rush |

Paper stock Paper stock

|

10pt to 28pt (60lb to 400lb) eco-friendly Kraft, e-flute corrugated, bux board,

cardstock |

Proof Proof

|

Flat view, 3d mock-up, physical sampling (on Request) |

Embossing and Debossing

A process that creates a raised or recessed pattern on the surface.

Dimensions

Dimensions

Min.quantity

Min.quantity

Default process

Default process

Printing

Printing

Options

Options

Turn around time

Turn around time

Paper stock

Paper stock

Proof

Proof