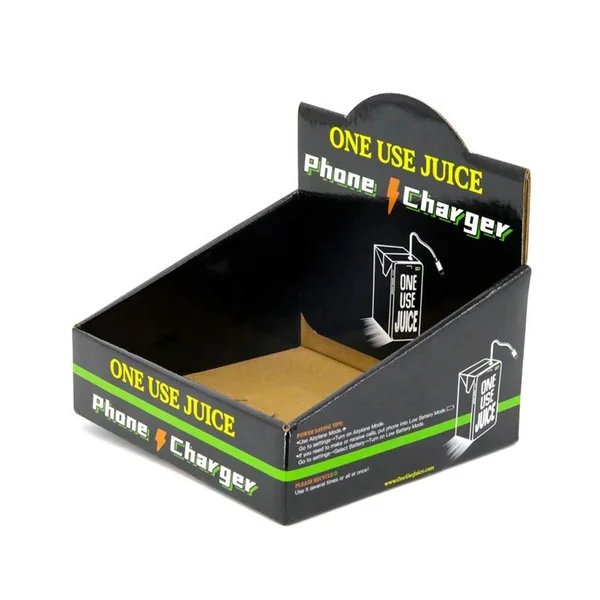

An Auto Bottom Tray is a type of packaging solution used in various industries, particularly in the realm of product packaging and shipping. It is designed to be convenient, secure, and easy to assemble. The key feature of an Auto Bottom Tray is its automatic locking mechanism, which allows it to quickly and securely snap into place without the need for tape or adhesive. This design not only saves time during assembly but also ensures the package's structural integrity, making it suitable for transporting and storing a wide range of goods, from electronics to food products. Auto Bottom Trays are versatile and can be customized in terms of size, shape, and design, making them an ideal choice for businesses looking for efficient and reliable packaging solutions.

What is an Auto Bottom Tray?

The Auto Bottom Tray is a versatile and efficient packaging solution that simplifies the assembly process for various products. This innovative tray design features an automatic bottom that easily locks into place, ensuring quick and secure packaging without the need for adhesives or tape.

Industries and Applications of Auto Bottom Trays

The Auto Bottom Tray is commonly used in industries such as food, retail, and e-commerce due to its convenience and reliability. It provides a strong and stable base for items, preventing them from shifting or falling during transportation. This tray is often used for packaging items like confectionery, electronics, cosmetics, and other consumer goods.

Key Benefits of Using Auto Bottom Trays

The key benefit of the Auto Bottom Tray is its ease of use. To set it up, you simply push down on the centre of the tray, and the bottom automatically locks into place, creating a sturdy base for your products. This feature not only saves time during the packaging process but also reduces the need for additional packaging materials.

Overall, the Auto Bottom Tray is a cost-effective, time-saving, and environmentally friendly packaging solution that enhances product protection and presentation, making it a popular choice for businesses looking to streamline their packaging processes.

Dimensions Dimensions

|

All custom sizes & shapes |

Min.quantity Min.quantity

|

50 Boxes ( Hardproof Sample Option Available ) |

Default process Default process

|

Die cutting, gluing, scoring, perforation |

Printing Printing

|

Cmyk, pms, no printing |

Options Options

|

Custom window cut out, gold/silver foiling, embossing, raised ink, pvc sheet.

|

Turn around time Turn around time

|

10-12 business days , rush |

Paper stock Paper stock

|

10pt to 28pt (60lb to 400lb) eco-friendly Kraft, e-flute corrugated, bux board,

cardstock |

Proof Proof

|

Flat view, 3d mock-up, physical sampling (on Request) |

Embossing and Debossing

A process that creates a raised or recessed pattern on the surface.

Dimensions

Dimensions

Min.quantity

Min.quantity

Default process

Default process

Printing

Printing

Options

Options

Turn around time

Turn around time

Paper stock

Paper stock

Proof

Proof