Frequently Asked Questions

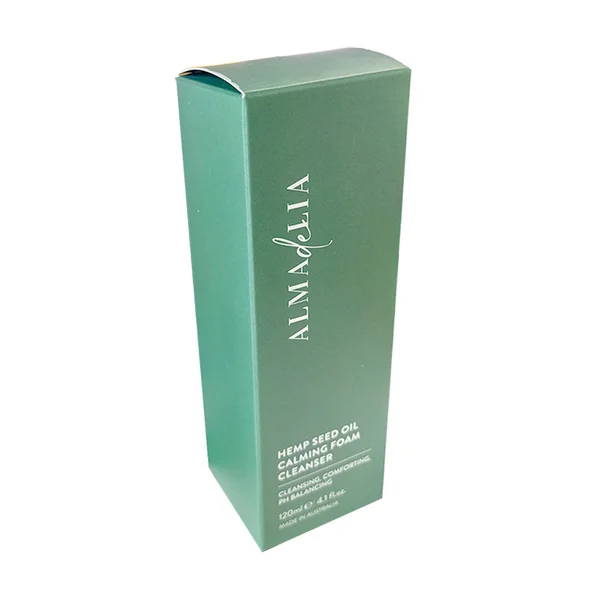

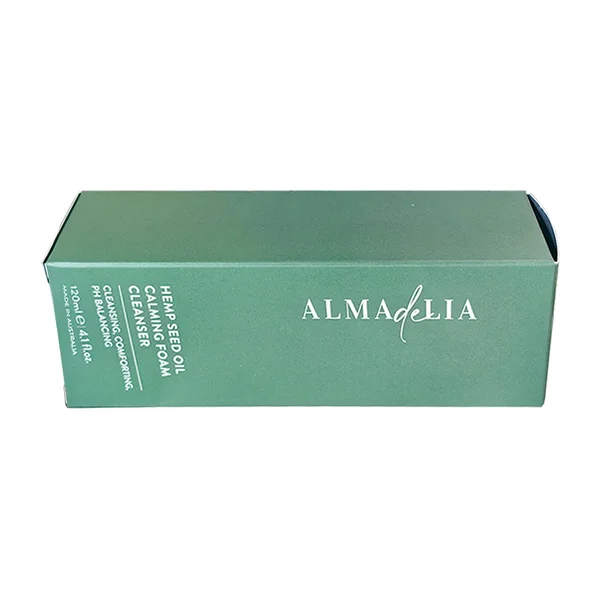

Reverse tuck end boxes are a type of packaging commonly used for retail products. They feature a design where both the top and bottom flaps of the box tuck in opposite directions for closure. These boxes are versatile and suitable for various products such as cosmetics, electronics, food items, and more.

Reverse tuck end boxes can be constructed from a variety of materials, including cardboard, paperboard, and corrugated board. The choice of material depends on factors such as the weight and fragility of the product, as well as the desired aesthetic appeal and environmental considerations.

Yes, reverse tuck end boxes are highly customizable to accommodate branding and packaging requirements. Customers can choose from various options such as different sizes, shapes, printing designs, and finishes. Customization allows businesses to create unique packaging solutions that reflect their brand identity and attract consumers' attention on the retail shelf.

Dimensions

Dimensions

Min.quantity

Min.quantity

Default process

Default process

Printing

Printing

Options

Options

Turn around time

Turn around time

Paper stock

Paper stock

Proof

Proof