Custom Tuck End Boxes

Custom tuck end boxes hold a special place in the cardboard packaging industry. Various consumer industries enjoy the benefits of their versatility and practicality. These industries include retail, food, cosmetics, and many more.

Design Flexibility of Custom Tuck End Boxes

This flexibility comes in handy when the requirement is to pack a wide range of products. They can have window cuts, allowing product protection and visibility simultaneously. The cosmetics and food industry especially benefit from this capability.

Tuck boxes also offer immense flexibility in their material selection. While cardboard remains their primary manufacturing material, it may come in different finishes and thicknesses. The consumers can choose whatever style best suits their purpose, from standard corrugated cardboard boxes for added strength to specialty finishes for a unique look and feel.

The color choices for such boxes are practically limitless. Consumers can make them match their branding themes and choose between matte or gloss finishes, which adds volumes to their packaging appeal and appearance.

Tuck-end boxes may also have different types of closures. Friction locks, automatic lock bottoms, and magnetic closure boxes are just some options that consumers may benefit from. Tuck and tongue end is another popular closure style for such packaging. In this type of closure, one end of the box has a tongue-like extension, while the other has a slot or a tuck flap. The consumers insert the tongue into the slot, which creates a secure closure. They can also have flaps that are glued together during assembly. This provides a permanent and tamper-evident closure. It's particularly useful for products that require maximum security, such as pharmaceuticals or sensitive electronics.

Durability

The fact that Tuck-End Boxes can be manufactured with various thicknesses of material lends them immense durability. This helps ensure they can protect the contents during shipping and handling. This durability is especially crucial in industries where products must be safeguarded from damage. Achieving durability with these boxes involves carefully considering materials, design, and construction techniques.

Easy Assembly

We send our consumers clear and straightforward assembly guidelines with each piece of custom packaging. These instructions include step-by-step illustrations and textual explanations on assembling the box into its perfect shape without hassle.

We also offer custom tuck boxes with pre-folded and pre-glued features. In this case, the critical we pre-glue the critical creases and certain flaps of the box to reduce the time and effort that our customers may require for assembling them.

Die-cut scores and indentations can also be incorporated into the design to create natural folding box lines. It makes it intuitive for the customer to fold the box into its final shape. We aim for a free-of-tool assembly for our tuck ends where consumers do not need any external elements to assemble their packaging. Our live and vigilant customer support also ensures that our customers are not uncomfortable at any point, during and after their order processing.

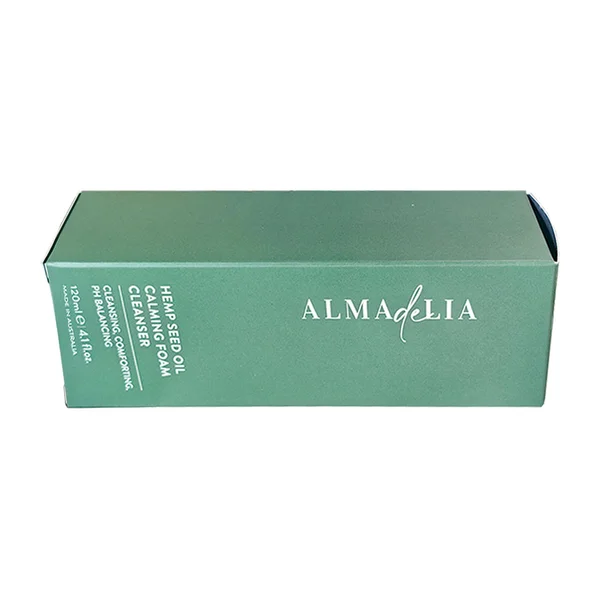

Branding Opportunities

Printed Custom Tuck End Boxes give extensive branding opportunities to their users. They can easily house full-color prints, embossing, or foil stamping, making incorporating logos, images, and texts possible. Such boxes offer an ideal canvas to create a strong brand presence. Consumers can prominently place their logos on them, ensuring that it is one of the first elements their customers see. This contributes to brand recognition and recall as well. Consumers can also maintain their branding consistency with such boxes. This includes using the same colors, fonts, and designs as their marketing material, reinforcing brand identity.

We can incorporate interactive elements like QR codes and barcodes in tuck boxes. They can lead the customer to a more personal interaction platform with their brand.

Sustainability

From the selection of FSC-certified paperboards to employing soy and plant-based inks, we offer all sorts of sustainability options for our sustainable custom tuck end boxes. These options help our customers achieve their sustainability goals in a wholesome manner. Our inks produce much less volatile organic compounds and are much easier to recycle. We also encourage our clients to go with a minimalist design approach. For this reason, we have trained designers who design the most impactful illustrations using minimalist designs and styles. We also advocate using eco-friendly coatings such as UV and water-based varnishes on the boxes. They require much less energy to cure and enhance the box's appearance. We refrain from implementing such practices during our boxes' manufacturing process, which may hinder their recyclability.

Types of Custom Tuck End Boxes

The choice of customization means the choice of freedom. The styles and types of boxes we offer with tuck ends are unlimited. We design them to provide specific functionalities and aesthetics. However, some common types of custom tuck boxes include:

Straight Tuck Boxes

This is the most common style of tuck packaging, where both the top and bottom flaps tuck in the same direction. This style is handy and suitable for a wide range of products. It is also much less costly since it requires no special mechanical alterations.

Reverse Tuck End Boxes.

The only difference between straight and reverse tuck end boxes is that in this type, the flaps tuck in the reverse direction, opposite each other, making them the ideal type of packaging for frequent use and access.

Auto Lock Bottom Tuck end boxes

This style has a pre-glued bottom that auto-locks when the box is unfolded. This provides additional support to the box's structure. These boxes are also very easy to assemble.

Snap Lock Bottom Tuck End

When the consumers unfold the box, the snap lock bottom tuck end's bottom part snaps into its place. They are very stable and often come in use for heavier products.

Full Overlap Tuck End Boxes

This type of packaging has flaps that completely fold over each other when the consumer closes them. It offers extra protection to fragile and breakable items.

Partial Overlap Tuck Boxes

This style is particularly suitable for objects that require protection and ease of access. The flaps overlap partially when closed.

Gable Tuck End Boxes

Gable tuck end boxes have a distinctive gable-style top, making them stand out on retail shelves. They are often used for packaging gifts, snacks, and specialty products.

Customboxesonly.com offers customers all the styles mentioned above and extensive customization opportunities at exclusive prices and discounts. Our wholesale custom tuck-end boxes promise savings and long-term benefits.