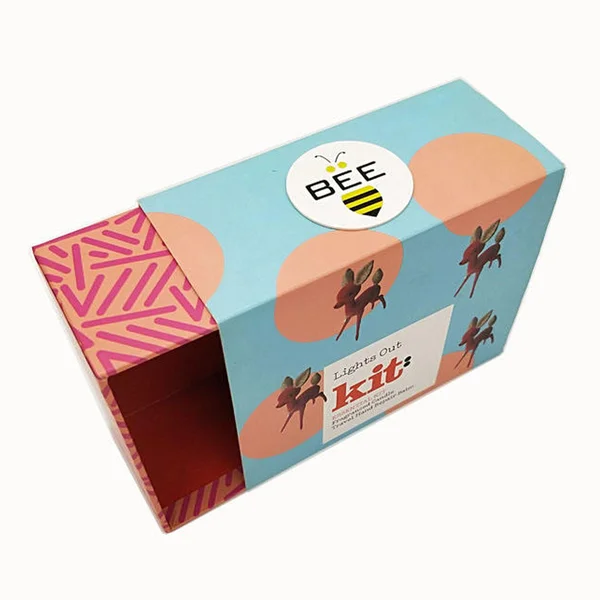

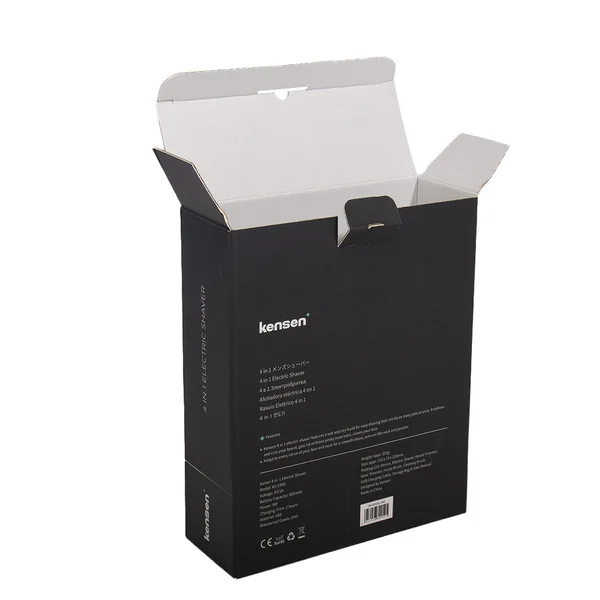

A custom hard drive packaging box makes products stand out in retail settings from the competitors. It comes in several unique size options and color combinations. Customers may peep inside the boxes due to their uniquely crafted die-cut windows. They come with special add-ons like inserts and placeholders that help to expertly arrange the products inside the box. Their handles' distinctive shapes enhance their appeal and make them easier for customers to carry. Some consumers like custom rigid hard drive packaging boxes with internal embellishments like internal printing, velvet lining, and foam inserts. The best materials used in their production include kraft, bux board, and corrugated. They are reusable, recyclable, and biodegradable. Due to their endurance, these materials ensure the safety of packaged items during transportation. Custom-printed hard drive packaging boxes feature printed product information, illustrations, photos, and relevant graphics. These printing components boost revenue by bringing in the targeted clients. Most consumers go for contemporary printing techniques like lithography, offset, and digital printing to print high-quality boxes. To further emphasize their appeal, a range of decorations are also offered, such as matte or gloss coating, raised ink, embossing, silver or gold foiling, and others.

Hard Drive Packaging Box

Hard drives are sensitive to electrostatic discharge because it can damage the components of the hard drive. This is why the best hard drive packaging box is made from antistatic materials like bubble wrap, foam, and cardboard. Since hard drives are also prone to accidental damage, cushioning materials like foam inserts and air-filled wraps are added to the box. The box has a secure closure to avoid accidental opening during shipping. These closures may also have adhesive strips, tabs, or interlocking flaps for extra protection. The box has clear labels with information such as contents, handling instructions, and any relevant warnings. It may have branding options such as color choices and compelling graphics to make the box marketing worthy as well. Industry-specific regulations and guidelines are also a part of such a box, ensuring compliance with the set standards.

The necessity and importance of having a hard drive packaging box, especially for hard drives, is rooted in several crucial factors. These factors include protection, transportation, and the overall customer experience that people have while using hard drives. Our hard drive packaging takes into account all of these factors and comes up with the best possible solutions. Here are why such boxes are a must-have.

Protection from Physical Damage via Hard Drive Packaging Box

These delicate electrical components have numerous sensitive internal parts. They can damage easily due to shocks, vibration, or any minor drop. A packaging box that is specifically for them takes into account all of these uncertainties and offers a protective barrier against these external forces. This reduces the risk of damage during shipping and handling.

Preventing static electricity

Hard drives are highly susceptible to electrostatic discharge. This component can pose irreparable damage to the circuitry inside. Proper packaging materials such as antistatic bags and homes help to dissipate static electricity. This is why we offer custom hard drive packaging box made from completely nonstatic materials.

Organized storage

manufacturers and customers both benefit from the organizing capacity of packaging boxes. Other boxes allow for easy categorization, labelling, and handling of hard drives. They also help our customers to streamline inventory management and retrieval processes without any hassle.

Enhanced customer experience

Our well designed packaging boxes contribute to an overall positive customer experience. When customers receive a hard drive in a sturdy and well labeled box, they develop confidence in the product and its manufacturer. Leading to repeat business and positive reviews.

Compliance with regulations

We understand that in some industries, there are regulations and standards governing the packaging and transportation of electronic components. This is why we make specialized packaging that meets these standards, ensuring compliance and avoiding potential legal issues.

Eco-friendly considerations

We truly trust that packaging boxes can also address environmental concerns. We use eco-friendly packaging materials and designs that reduce the environmental impact of packaging while meeting sustainability goals.

Professional presentation

We understand that a dedicated hard drive packaging box communicates professionalism and attention to detail. It gives a certain assurance to the customers that the manufacturer cares about product safety and presentation. This can increase the trust and customer satisfaction of a brand.

Box styles that can elevate a hard drive packaging box

The best box style for hard drive packaging depends massively upon the level of protection that the hard drive needs. Here are some box styles that can bring out the best of the best features of these fragile data keepers.

Corrugated boxes

Advantages: corrugated boxes are versatile and cost-effective. They come in varied thicknesses, which makes them capable of offering different levels of protection. They are also lightweight, which helps to reduce shipping costs.

Best use cases: they are highly suitable for standard hard drives since they can provide them with excessive protection without extra costs. They can also market a brand effectively due to their branding capabilities.

Rigid boxes

Advantages: they provide excellent protection for hard drives. They have a high level of crash resistance and impact protection. They can give out premium finishes, making them ideal for high-end or branded heart drives.

Best use cases: Rigid containers are suitable for premium hard drives, luxury electronics, or situations where a premium presentation is a necessity.

Folding cartons

Advantages: they're lightweight and cost-effective, suitable for smaller hard drives. They're also best to come in use for a packing that does not require a high degree of crush resistance. They can have special finishes and custom styles.

Best use cases: They often come in use for retail packing of hard drives or as inner packaging within a larger shipping box.

Mailer boxes

Advantages: they offer easy assembly and can ship smaller hard drives and accessories. They offer basic protection and can have all the necessary printing and branding of the manufacturer.

Best use cases: they are perfect for compact hard drives, SSDs, or accessories when one wants a convenient packaging solution for online sales.

Die-cut boxes

Advantages: digit boxes can fit the exact dimensions of the hard drive. Hence providing a snug and foolproof fit. This factor minimizes the possibility of movement during transportation, enhancing protection. One can get them in both corrugated and paperboard materials.

Best use cases: they are suitable for hard drives that require a precise fit and extra protection against movement and shock.

Display boxes

Advantages: they showcase the product while providing protection. The transparent window is suitable for retail environments, which allows the assessment of a hard drive without putting it at risk of mishandling.

Best use cases: they are best for retail packaging of hard drives, especially when one wants to highlight the products' features.

The choice of the best printed hard drive packaging box depends on how the consumers want it to look. Branding objectives play a major role in deciding what needs centre stage on a product's packaging. Custom printing and the addition of foam inserts can further enhance the packaging functionality and appeal.

Conclusion

A hard drive packaging box can turn out to be the decisive factor for the prosperity, safety, and marketing of a hard drive. customboxesonly.com makes each and every one of its packaging solutions with equal care and love. Yes, what differentiates our products from our competitors is the love that we put into each piece of packing that we make. Even if the order is for a wholesale hard drive packaging box, the amount of care, quality check, and attention to detail remains the same.

Dimensions

Dimensions

Min.quantity

Min.quantity

Default process

Default process

Printing

Printing

Options

Options

Turn around time

Turn around time

Paper stock

Paper stock

Proof

Proof