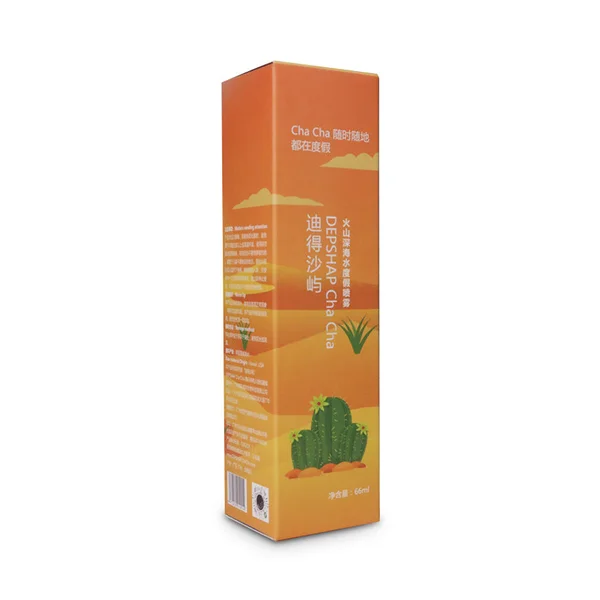

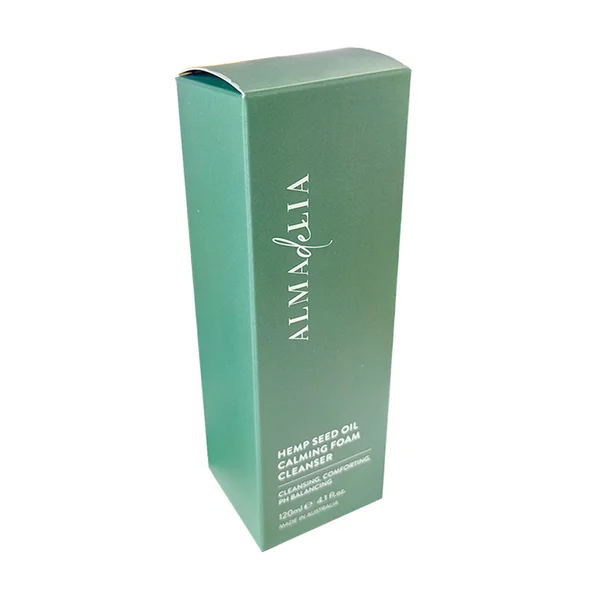

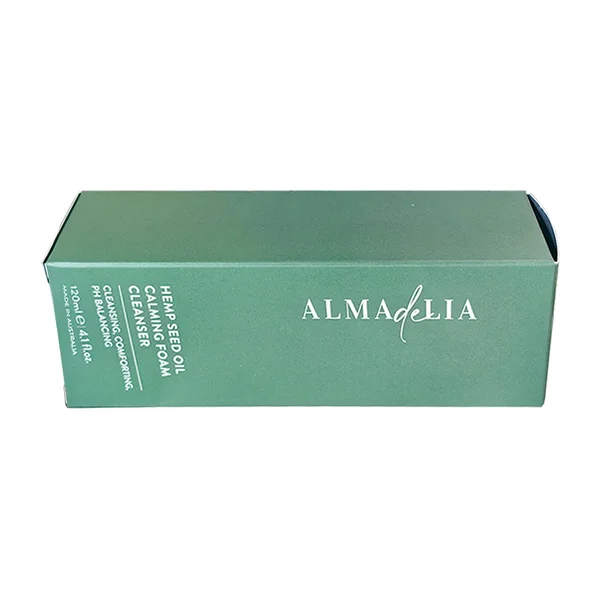

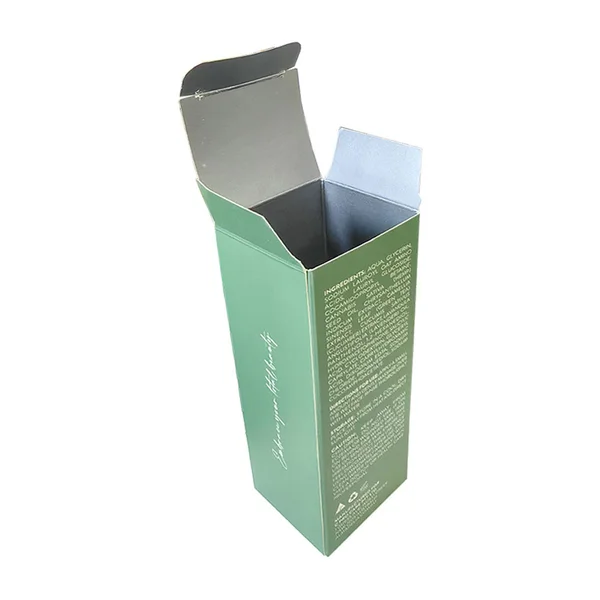

In custom reverse tuck end boxes, the opening flap on the bottom side is attached to the back of the custom box, and this flap tucks into the front. Similarly, the top opening flap is attached to the front and folds over the back. Materials like kraft, bux board, and corrugated are used in their production for further strength and robustness. They guarantee product safety by shielding the items from potential hazards during handling and shipping. These custom rigid reverse tuck end boxes are reasonably priced because they are made from natural materials. Environmentally beneficial binders and adhesives are utilized in their production. Some users purchase personalized boxes with die-cut windows. They come with magnetic or Velcro lids for added security and custom-shaped handles to make their carriage easier.

They accurately represent the packaged items with printed graphics and imagery. Custom-printed reverse tuck end boxes have the brand's logo and name printed on them to make it easier for buyers to distinguish a brand's products in stores. They are printed using environmentally friendly ink. High-quality printed boxes are produced using contemporary printing techniques like offset printing, lithography, and digital printing. They also feel opulent due to surface finishing options like embossing, PVC, foil stamping, coatings, and foiling.

Reverse Tuck End Boxes

In the case of reverse tuck end boxes, the top flap that opens the box is attached to the front and tucks into the back, while the bottom flap that opens the box is attached to the back and tucks into the front. These boxes are available in all desired shapes and customized sizes. They can also come in more than one color. Their production substances may be cardboard, card stock, or Kraft paper. These materials are safe for the environment because they are reusable and recyclable. They can also come with printed drawings, pictures of the product, and other printing elements. There are many ways to finish their surfaces to make them look better. These options may include foiling, embossing, raised ink, and others.

Reverse tuck end boxes are famous for being strong and lasting long. They can keep the packaged items safe for a longer time. You can also imprint beautiful pictures on these boxes to positively impact your customers. You can get this attractive packaging from us to attract more customers.

Get customized reverse tuck end boxes.

There is a trend in the modern world where all brands try to make a good impact on their customers. They try to choose custom boxes with certain features according to their needs. Companies put a lot of thought into how they package their products. Depending on your creative ideas, you can get this packaging in any style you want. Our package creators will create the best box shape that you want. You can request the creation of pillow-style, rectangular, square, or cubic shapes of boxes. We can also help you create modern shapes like pentagonal, hexagonal, briefcase-style, and prism-shaped boxes.

You can also request our manufacturing team to add special features inside the box. For instance, you can get it with custom-sized inserts to fit your products. There can also be multiple inserts to hold two or more products. We also create packaging with custom-shaped handles. You can request the addition of ribbon handles and PVC patching cards. We also add custom-shaped airtight lids to prevent the entry of dust. There can also be personalized windowpanes. They will let buyers see inside the box. You can also request our team to print drawings, graphics, and textual details inside the box.

Reverse tuck end boxes with impressive printing.

We know that product packaging doesn't look good without printing. You must print important graphics or text on your packaging to make it interactive. We can use the most advanced technology for printing. We have the best printing tools to ensure the best quality printing. When you need to print a lot of boxes, we offer offset and screen printing. But if you only need to print a few boxes, you can choose digital printing. customboxesonly.com uses soy-based inks, water-based inks, or fluorescent color inks. You can also request our team to use CMYK, PMS, or oil-based inks for printing.

Paper stock and materials

The most important goal of packaging is to keep the product safe. If your product package can't protect what's inside, it is not good for your products. We manufacture custom boxes from stronger materials. We use thicker materials that can be anywhere from 10pt to 28pt thick, depending on what the brand wants. Our production materials include black, white, and brown kraft, metallic paper, and textured paper. We also ensure that the production materials, glues, and binders are good for the environment.

Finishing options and add-ons

We have started using various modern finishing options to give your packaging a stunning appeal. For instance, you can request our team to add silk lamination, aqueous coating, and anti-scratch lamination. We can also manufacture packaging with waterproof lamination, soft-touch coating, and gloss coating. There are also several add-ons to enhance the worth of your product packaging. We can also use embossing, cold foil stamping, debossing, and hot foil stamping. These methods can help to imprint text or graphics. We can also use these techniques to imprint the logo and name of your brand.

What separates us from others?

customboxesonly.com has made a good name in the market by giving customers various free services. For example, we can ship custom-printed boxes anywhere in the country for free. Clients can also ask for shipping outside of the country for a small fee. We also offer an exemption from plate charges and die-cut fees. We handle orders quickly because we have a professional team and reliable tools. Our team can ship standard orders of reverse tuck-end boxes in 10–12 business days after receiving payment. We can also offer the facility of rush delivery with a small fee. We can send rush orders in 6-8 working days. Our customer service team works hard to help our clients at all times. You can reach our team by phone, live chat, or email.

Dimensions Dimensions

|

All custom sizes & shapes |

Min.quantity Min.quantity

|

50 Boxes ( Hardproof Sample Option Available ) |

Default process Default process

|

Die cutting, gluing, scoring, perforation |

Printing Printing

|

Cmyk, pms, no printing |

Options Options

|

Custom window cut out, gold/silver foiling, embossing, raised ink, pvc sheet.

|

Turn around time Turn around time

|

10-12 business days , rush |

Paper stock Paper stock

|

10pt to 28pt (60lb to 400lb) eco-friendly Kraft, e-flute corrugated, bux board,

cardstock |

Proof Proof

|

Flat view, 3d mock-up, physical sampling (on Request) |

Embossing and Debossing

A process that creates a raised or recessed pattern on the surface.

Dimensions

Dimensions

Min.quantity

Min.quantity

Default process

Default process

Printing

Printing

Options

Options

Turn around time

Turn around time

Paper stock

Paper stock

Proof

Proof