Welcome to our phenomenal collection of custom electronic boxes. Take your pick from materials such as corrugated, fiberboard, plastic injection molds and lightweight yet protective Styrofoam. Eco-friendly materials, recyclability and cost-effectiveness are all considered in our various sustainable packaging options. Our electronic boxes, with emphasis on protection and appeal among other things, let your brand identity shine through while at the same time promoting customer loyalty.

Introduction

When you acquire electrical devices that come in drab and uninspiring packaging, do you find it frustrating? If that is the case, you are not the only one. Effective package design is more important than it has ever been in the electronics sector, which is now seeing significant growth.

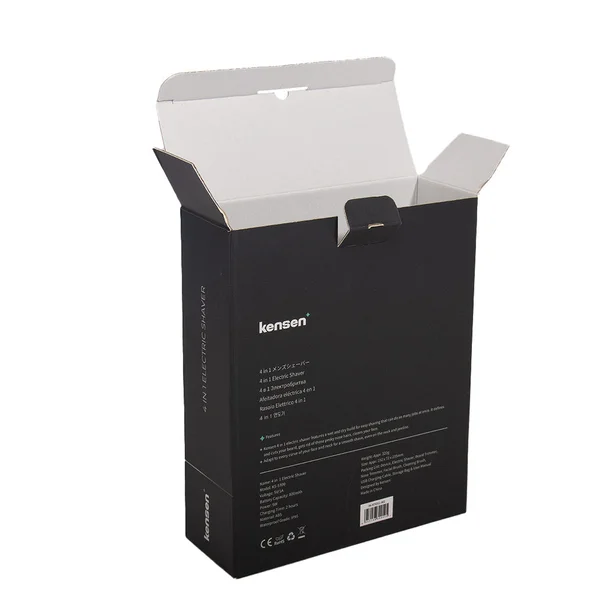

Special packaging for shipping electrical items, especially rigid boxes are absolutely necessary. The packaging techniques mentioned here are intended to prevent sensitive electronic devices from incurring damage caused by shock, vibration, or other environmental phenomena.

Common Box Types for Packaging Electronic Products

Electronic packaging boxes are produced using several materials with differing properties to suit various design and functional requirements. In choosing suitable packaging for electrical products, it is necessary to consider several factors: the materials used, box types available, size and form characteristic demands. And then there are elements of the brand itself. The following is a list of materials and styles widely used for packaging electronic device boxes:

Electronic devices have four different materials for boxes.

i. Corrugated Boxes: But they not only are light and strong, cardboard-based boxes also afford a great deal of choice in terms of measurements and contours.

ii. Boxes made of fiberboard: These long-used boxes are especially well suited for the packing of delicate, heavy electrical machinery since they are made from good quality cardboard. They can withstand high water pressure and give good shock absorption.

iii. Plastic Injection Molds: These strong boxes are used to box up expensive or delicate things. They are made of high-quality plastic and are renowned for their toughness. Their water, dust and moisture resistance is especially good, and they can absorb stress well.

iv. Styrofoam Boxes: These boxes, made of expanded polystyrene foam, are the ideal choice for packing items that need cushioning and protection. These materials have great cushioning capabilities, yet are quite light.

Electronic packaging boxes can be categorized into five distinct styles:

Straight-Wall Style:

- Description: This style has straight sides with no curves or dips.

- Function: A basic, simple enclosure for electronic things.

Flap-Lid Style:

- Description: This kind of container incorporates an opening flap that is easy to open and close, which is convenient for dealing with frequently revised items, such as electronics and accessories.

- Suitability: Suitable for products requiring frequent upgrading or revising.

Hinged Box:

- Description: The packaging design features a hinged lid for consumers to more easily reach the product.

- Advantage: Good choice for products requiring frequent upgrades or changes.

Display Boxes:

- Description: To display the highlighted merchandise, such boxes often have a plastic cover or see-through glass so that customers can have a look at the product before buying.

- Purpose: Emphasizes product visibility during the buying process.

v. Acrylic Display Boxes:

- Description: Though made of acrylic, these boxes are lightweight, designed to be taken to trade fairs and exhibits.

- Protection: Provides better protection against dust, moisture, and environmental factors.

As for the field of guarding and displaying a wide variety of items, from consumer electronics to fragile parts and heavy appliances, packaging is another indispensable element. But product packaging solutions have to be tailored to meet the special needs of each product.

Box Manufacturing Process

The factors mentioned above fall into two categories: the construction of the box and the method of closure, which must afford adequate protection and promotion for the items inside.

1. Packaging for Consumer Electronics (such as smartphones, headphones):

- Electronic products packaged in boxes should be securely packed up, and keep the precision components that require welding from being damaged by transportation or handling.

- use packaging design materials with sufficient padding and protection, combining customized packaging technology for ideal outcomes.

- When designing an electronics box, think about using custom inserts or compartments to house and organize different components securely.

- Design boxes, and packaging schemes that minimize material waste and maximize space efficiency.

2. Fragile or Sensitive Electronic Components Packaging:

- Take protective layers and solder Also, use antistatic materials to prevent fragile electronic parts from being destroyed by an electrostatic field.

- Add shock-absorbing components such as foam padding or air-filled cushions so that the boxes can resist unwanted vibrations, and protect delicate parts.

- Take temperature-sensitive components into account and insulate where required.

- On packaging, give clear instructions or symbols to prevent mishandling or breakage due to wrong handling of solder.

3. Large Appliances or Equipment Packaging:

- Creating sound packaging applications adequate to the size and weight of larger electronic products.

- Adding reinforced corners or edging in the packaging enhances rigidity of structure during transit. This must be made from high-quality solder.

- Try to think in modular terms for ease of disassembly if recycling is an issue, with environmentally friendly materials and as little soldered joints as possible.

- Add handles or grips for easy lifting and moving.

4. Sustainable Packaging Solutions:

- Use eco-friendly materials like recycled cardboard and biodegradable plastics. Avoid toxic materials like solder that can pollute the environment.

- According to the type of solder used in the process, it is necessary to optimize package sizes, reducing material use and carbon emissions from transportation.

- Look for other ways to package: reusable boxes or the minimalistic look.

- Through labels of sorts, you should clearly communicate to the consumer that the packaging is recyclable.

Six Design Tips for Electronic Packaging Boxes

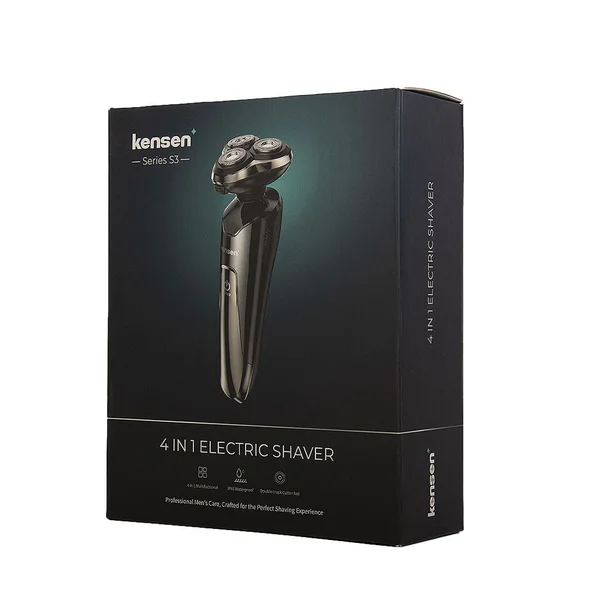

Electronic packaging boxes are a very important step in the overall packaging, marketing, and branding of any electronics company. Here are key tips to consider:

1. Protection

Design the packaging box to keep the product safe from impact, moisture and other such dangers in shipping.

2. Appeal

Packaging should be eye-catching and point up the product's advantages over its competitors.

3. Convenience

Design convenient packaging that can be opened, closed, handled and stored easily; with clear instructions and labels for a good customer experience.

4. Cost-Effective

Packing should be cost effective in terms of shipping costs but still provide adequate protection.

5. Sustainability

Create recyclable, environmentally friendly packaging which is also not harmful to the earth.

6. Brand Identity

The aim is to have the packaging reflect the company's design principles, values and style. In doing so, they reinforce brand identity and create favorable associations with customers that promote loyalty.

Choose CBO for Your Brand

If you need a manufacturer of wholesale electronic boxes, choosing the top manufacturing and providing wholesale custom solutions for your brand's needs. Let the skill of CBO experts make your packaging stand out, and leave a lasting impression in the market.

Dimensions

Dimensions

Min.quantity

Min.quantity

Default process

Default process

Printing

Printing

Options

Options

Turn around time

Turn around time

Paper stock

Paper stock

Proof

Proof