Your product’s packaging and shipping are important things to consider. There is a vast array of shipping containers on offer. In such a case how do you determine which one is better suited for your needs? Let's take heed of this brief overview to crack the differences between cardboard packing containers and shipping boxes. Get some coffee and tea and travel with us along the differences between cardboard boxes and shipping boxes.

Cardboard boxes

We also know them as Corrugated boxes. They commonly come in use for packaging and transportation. Their strength and durability come due to the use of multiple layers of paperboard.

These boxes are useful for almost all types of products since they are immensely customizable. The airy, lightweight, and simple nature of cardboard makes it an excellent choice for shipping. Boxes of cardboard also reduce the weight of packages.

Manufacturers can easily customize them with logos or labels. This gives your brand a professional appearance. Containers that are made of cardboard also have an environmentally sustainable nature. This is because Recycled materials come into use in their production. One can also recycle them again after use. By choosing cardboard instead of plastic, you can save a large amount of money and increase the durability of your product. Additionally, these containers also give excellent control for delicate items during transportation.

The construction of these boxes has flutes. This offers added rigidity and impact resistance. At the same time, the outer shell serves as an additional barrier against moisture and dust. One thing that is noticeable here is that boxes of cardboard material are not suitable for heavy-weight items. They are also not so good for products that require additional support. The packaging and logistics industry heavily brings custom packaging containers into use. It is because this practice offers advantages such as cost-effectiveness, flexibility in size, customization options, recyclability, and protection during shipping.

Shipping boxes

Packaging vendors design such boxes to withstand the toughness of transportation. This makes them stronger than standard cardboard packaging boxes.

The use of thicker corrugated cardboard in these product boxes enhances their durability and suppleness. They prove to be true protectors of fragile or valuable items during transit.

Two flat liner boards are supplied with multiple layers of cardboard flutes to make these boxes. This makes us understand how they are so strong. Mostly the size of these boxes is standard. This is because shipping companies have specific and set requirements for their weight and dimensions. One can say that this is another one of their advantages. Businesses may get to avoid any extra penalty charges or delays in shipments by using standard boxes during shipping.

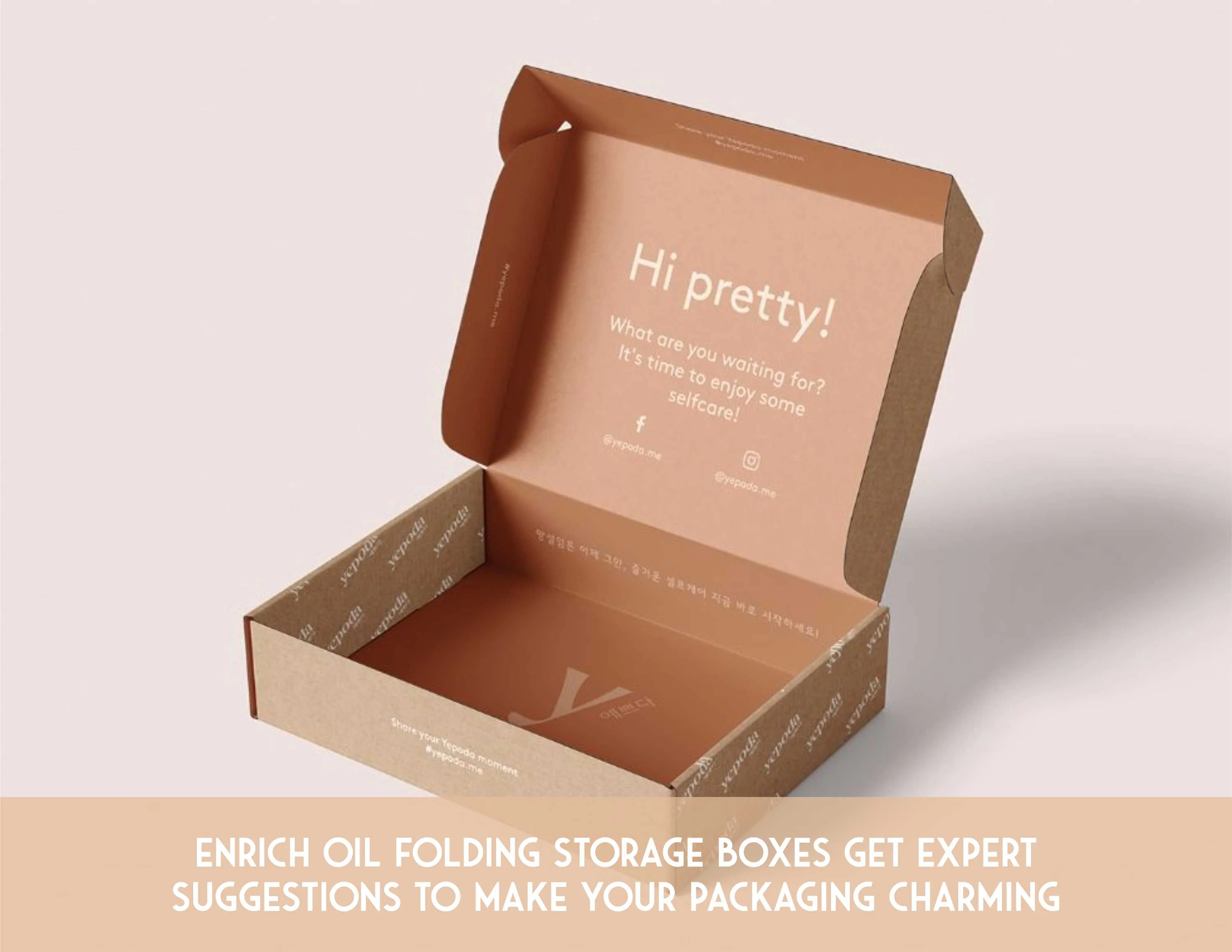

The use of shipping boxes can also benefit businesses in terms of branding.

Adding branding gimmicks on shipping containers is becoming somewhat of a habit. This type of branding often includes logos or slogans. This practice immensely helps in brand recognition. It also helps in portraying a professional touch when a buyer receives their shipment. These boxes may prove to be a little on the expensive side if we compare them with standard cardboard packaging boxes containers.

This is most probably due to the techniques that come in use to make them and their special features. Also, one must keep this fact in mind that such boxes are designed to travel. So they may not be as attractive or flashy as a retail cardboard box.

Although they may be more expensive and have less visual appeal. The benefits of product safety and efficient logistics are negated by these cost factors.

What sets cardboard boxes apart from shipping containers?

Although consumers use both types of these boxes interchangeably. There are some salient differences between them. Cardboard containers are commonly taken as any box made of cardboard. Various shapes and sizes can come in use for these boxes. This makes them the best choice for multiple packaging options. It is very easy to fold and join them. This makes them ideal if you need to store or transport large amounts of packaging for your products.

On the contrary, boxes for shipping are far more robust and resilient. They can be a bit of a trouble to handle before or after usage. They have reinforced edges and corners, which makes it further difficult to fit them in limited spaces.

Packaging vendors make them withstand the elements and provide ample protection for the items they carry.

How to choose the right cardboard box or shipping box

If you want to guarantee that your items will remain safe till they reach their end consumer. Then you have to choose the right type of box to pack them. You need to measure the exact size of your product to get a box that is appropriate for the items you are shipping. Too small and your items may not fit; too large and they may shift and damage.

You also need to consider how sturdy the box needs to be. This primarily depends upon the item you are shipping. If it's delicate or heavy, you have to opt for thicker, more durable cardboard.

You also have to give equal importance to the weight capacity. This is much simple than it sounds. Take the weight of your items and choose a box with a weight capacity that can handle them.

Analyze if your products need a box that is simple or do they require any special features. Some boxes come with built-in dividers or inserts that can help keep delicate or multiple items organized and secure during transit.

If you need to send out some message to the couriers or the handlers of your products. You need to get a customizable box. Such boxes can have custom warning signs on them to highlight the special needs of the packages to the handlers.

Conclusion

In the battle of cardboard boxes vs. shipping boxes, both options have their unique advantages and disadvantages.

Cardboard packaging containers are versatile, and they massively come in use. One can simply not deny that they are cost-effective and easy to customize for branding purposes. But the fact remains that they are susceptible to moisture, and they cannot carry heavy items.

On the other hand, shipping boxes offer superior strength and protection during transit. They are specifically designed to withstand the rigors of transportation, ensuring that your goods arrive safely at their destination. However, shipping boxes can be more expensive than cardboard alternatives.

When deciding between cardboard boxes and shipping boxes, consider factors such as the type of items you need to pack or ship, the distance of travel involved, budget constraints, and environmental considerations.

We can conclude this debate by saying that there is no one-size-fits-all rule in the world of packaging. Your choice will ultimately depend on your needs.